A Guide to Perishable Food Shipping Restrictions

Master perishable food shipping restrictions with our guide to federal, state, and carrier rules for temperature control, packaging, and labeling.

Cody Y.

Updated on Dec 26, 2025

Shipping perishable food involves a complex web of rules where a single mistake in temperature or packaging can mean spoiled products and serious financial losses. These perishable food shipping restrictions aren’t just suggestions; they are strict requirements set by federal, state, and carrier authorities to ensure every product arrives safe and fresh.

The High Stakes of Shipping Perishable Goods

Imagine your supply chain is a literal chain. For shelf-stable items, that chain is pretty tough. But for perishable goods, it’s a fragile cold chain where one weak link—a delayed truck, a cracked cooler, or an incorrect label—can break the whole thing.

Imagine your supply chain is a literal chain. For shelf-stable items, that chain is pretty tough. But for perishable goods, it’s a fragile cold chain where one weak link—a delayed truck, a cracked cooler, or an incorrect label—can break the whole thing.

This isn't just an analogy; it's the daily reality for eCommerce businesses selling fresh, refrigerated, or frozen products. Getting it right boils down to mastering three critical pillars.

The Three Pillars of Compliance

- Temperature Control: This is the absolute deal-breaker. Keeping products within the right temperature range, whether frozen or refrigerated, is the only way to prevent bacterial growth and spoilage.

- Proper Packaging: Your packaging is your first line of defense. It has to insulate the product, hold the coolant (like gel packs or dry ice), and survive the bumps and drops of transit.

- Accurate Labeling and Documentation: From simple "Keep Refrigerated" stickers to mandatory HAZMAT labels for dry ice, clear communication is a legal requirement that tells handlers exactly how to treat your package.

The financial stakes are incredibly high. In the global perishable goods transportation market, minor delays can cause spoilage rates as high as 30-40% for sensitive items like fruits and vegetables. That vulnerability is exactly why precise temperature control, often between 0-4°C, is so heavily regulated. You can read the full research about the perishable goods market to see the sheer scale of the challenge.

Let's break down the primary challenges you'll face and where the regulations come into play.

Key Challenges in Perishable Food Shipping at a Glance

| Challenge | Business Impact | Primary Regulatory Focus |

|---|---|---|

| Maintaining the Cold Chain | High risk of spoilage, customer complaints, and lost revenue. | Federal (FDA), State Health Departments, Carrier Policies |

| Incorrect Packaging | Product damage, coolant failure, rejected shipments. | Carrier Policies (UPS, FedEx), Federal HAZMAT (for dry ice) |

| Improper Labeling | Delays, mishandling by carriers, fines for non-compliance (especially HAZMAT). | Federal (DOT, FDA), Carrier-Specific Rules |

| Cross-State Regulations | Banned items (e.g., certain produce), different labeling laws, complex tax rules. | State Agriculture & Health Departments |

| Documentation Errors | Shipments held at borders or sorting centers, customs issues for international. | Customs (CBP), FDA, USDA |

Navigating these hurdles is fundamental to building a reliable and profitable perishable goods business.

Mastering these rules isn't just about avoiding fines or rejected shipments. It's about protecting your brand's reputation, ensuring customer satisfaction, and building a profitable business. A single spoiled delivery can lead to a lost customer and negative reviews that damage your brand's credibility.

Ultimately, a solid perishable shipping strategy turns these challenges into a competitive advantage. When you consistently nail these complex rules, you prove your reliability and commitment to quality—and that’s what builds lasting customer trust.

How Regulators Define Perishable Foods

So, what actually makes a food "perishable" in the eyes of a regulator? It's not just about a short shelf life. It’s a specific, science-based classification that dictates which perishable food shipping restrictions apply to your products. Think of it less like an opinion and more like a diagnosis based on a food's inherent characteristics.

The U.S. Food and Drug Administration (FDA) and the U.S. Department of Agriculture (USDA) don’t just eyeball it. They measure specific properties of a food to predict how quickly dangerous microorganisms can grow. This approach draws a clear, scientific line between foods that need strict temperature control and those that are perfectly safe on a shelf.

The Scientific Trio of Perishability

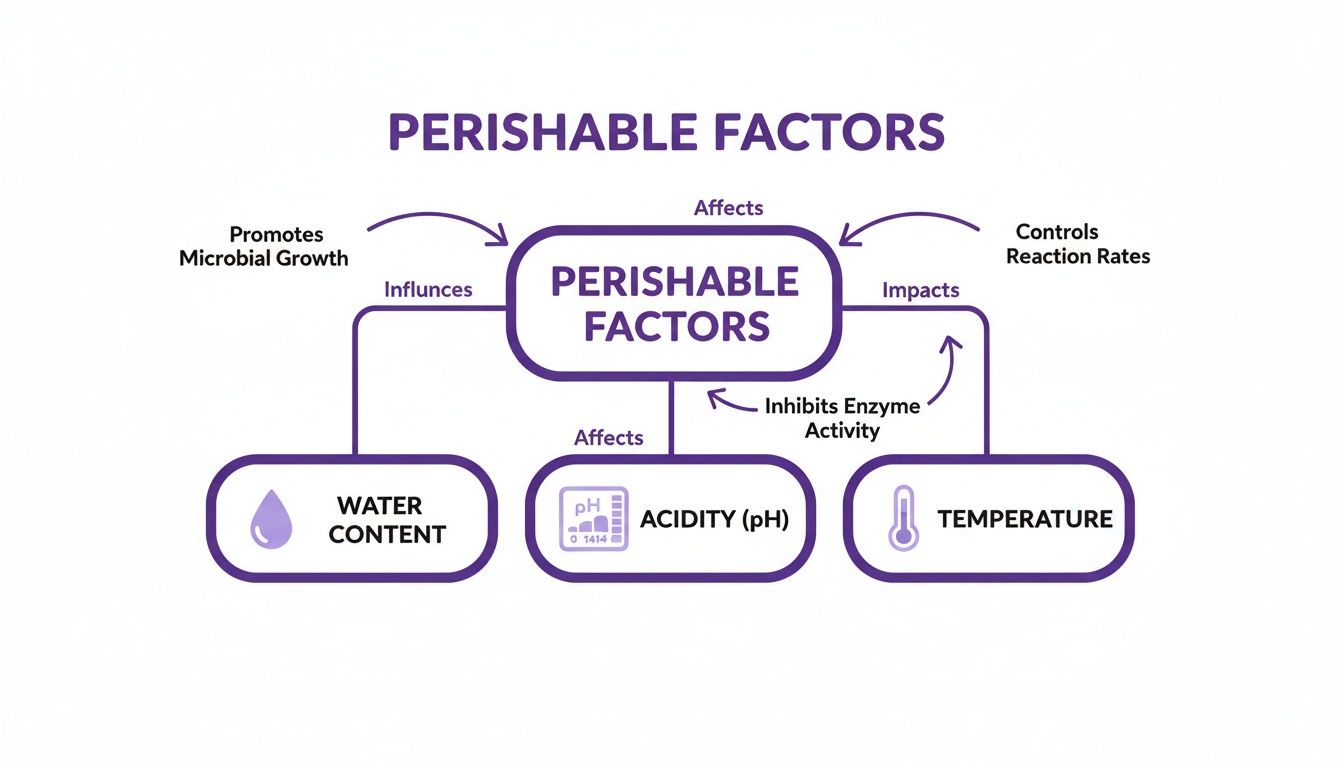

Regulators zero in on three key factors to decide if a food is what they call a Time/Temperature Control for Safety (TCS) food—the official term for most perishables. These three elements work together to create an environment where bacteria either thrive or die off.

-

Water Activity (aW): This isn't about how much water is in a food, but how much of that water is available for microbes to use for growth. A food can feel moist but have low water activity if the water is chemically locked up by salt or sugar. Foods with a water activity level of 0.85 or higher are usually considered perishable because there's plenty of free water for bacteria to multiply.

-

Acidity (pH): This measures how acidic or alkaline a food is. Most nasty bacteria really struggle to grow in highly acidic environments. Generally, foods with a pH level of 4.6 or lower are too acidic for common pathogens. This is the science behind why pickled cucumbers can sit on a shelf for months, while fresh ones spoil in a week.

-

Combined Factors: It gets interesting when a food is borderline on one of these measures. In these cases, regulators look at how the two factors interact. For example, a food with a slightly higher pH might still be safe if its water activity is extremely low, and the other way around.

Foods that require time and temperature control to limit pathogen growth are the ones that fall under the strictest shipping regulations. It’s this scientific definition, not just an expiration date, that dictates your packaging and shipping choices.

Putting It Into Practice

Once you understand these factors, you can see why different products get hit with different rules.

Take aged hard cheeses, for instance. The aging and salting process lowers their water activity, making them far less perishable than a soft, moist cheese like brie. It's the same story for vacuum-sealed cured meats like salami; their lower water activity and higher acidity give them a much longer shelf life without refrigeration compared to fresh ground beef.

Thinking about the strict environmental controls regulators demand, it's easy to see why things like specialized door installations for food processing plants are so critical. These facilities are engineered from the ground up to manage the very factors—temperature and humidity—that influence the safety characteristics regulators measure.

Common Categories and Their Rules

Using these scientific principles, regulators lump foods into broad categories with their own distinct shipping needs:

- Refrigerated Foods: This is your dairy, fresh meat, and prepared meals. They absolutely must be kept at or below 40°F (4°C).

- Frozen Foods: These products have to stay at 0°F (-18°C) or below to remain completely frozen. No exceptions.

- Fresh Produce: Fruits and veggies have their own quirks, but most need cool, humid conditions to keep from wilting and spoiling.

By figuring out your product's scientific profile—its water activity and pH—you can classify it correctly and know exactly which perishable food shipping restrictions you’re up against.

Mastering Cold Chain and Packaging Rules

Think of your perishable product as an ice cube on a hot summer day. The goal isn't just to get it from point A to point B—it's to get it there before it melts. This is the heart of the cold chain: an unbroken, temperature-controlled supply line that keeps your food safe and fresh from your door to your customer's.

Nailing this process, along with choosing the right packaging, are the two most critical skills you can have when shipping perishable foods. The moment a product leaves your climate-controlled facility, the clock starts ticking. Your packaging suddenly becomes its own tiny, portable refrigerator. This is where the rules get serious, dictating everything from insulation thickness to the exact type of coolant you can use.

Keeping Your Cool: Temperature Integrity

Maintaining the correct temperature isn’t a friendly suggestion; it’s a non-negotiable requirement. Different foods have strict temperature thresholds that must be held for the entire shipping journey.

- Refrigerated Foods: Fresh meat, dairy, and prepared meals need to stay at or below 40°F (4°C). Any warmer, and you’re rolling the dice with bacterial growth.

- Frozen Foods: Anything sold as frozen must remain at or below 0°F (-18°C). Even a partial thaw can ruin the product's texture and safety.

This is all about managing the factors that make food spoil in the first place: water content, acidity, and, most importantly, temperature.

As you can see, temperature is the one variable you have the most direct control over during transit. It's the lever you pull to slow down the natural process of decay, regardless of a food's water content or pH level. This is why getting the intricacies of cold chain management right is absolutely essential.

The Special Case of Dry Ice: A HAZMAT Deep Dive

Gel packs work great for keeping things refrigerated, but frozen goods often demand something colder: dry ice. This is where things get tricky. As soon as you put dry ice in a box, you’re dealing with a hazardous material (HAZMAT), at least as far as air transport is concerned.

Dry ice doesn't melt into a puddle; it sublimates, turning directly from a solid into carbon dioxide gas. If that gas gets trapped in a sealed container, the pressure builds up until the package ruptures or even explodes.

Carriers like UPS and FedEx don’t mess around with dry ice. Their rules are strict:

- Quantity Limits: You’re often limited to about 5.5 pounds (2.5 kg) of dry ice for air shipments unless you have a special contract.

- Ventilation is Key: Your package cannot be airtight. It must be designed to let the carbon dioxide gas vent safely.

- Label Everything: The box needs a Class 9 HAZMAT diamond label. You also have to mark it with "Carbon Dioxide, Solid" or "Dry Ice," and list the net weight of the dry ice inside.

Ignoring these rules can lead to massive fines, rejected shipments, and create genuine safety hazards for the people handling your packages.

Choosing Your Armor: Packaging and Insulation

The right packaging isn't a one-size-fits-all solution. It's a calculated combination of insulation and coolant, tailored to your specific product, the expected transit time, and even the weather forecast.

A smart packaging strategy is your first and best line of defense against spoilage. You need to pick the right tools for the job, balancing cost, performance, and compliance.

| Method | Best For | Compliance Notes | Pros | Cons |

|---|---|---|---|---|

| Gel Packs | Refrigerated items (1-2 days transit), produce, dairy | Generally non-hazardous, check airline policies for large quantities | Reusable, non-toxic, widely available, predictable cooling | Heavy, less cooling power than dry ice, can leak if punctured |

| Dry Ice | Frozen goods (-109°F/-78.5°C), long-duration shipping | HAZMAT for air transport. Requires Class 9 label, proper venting, and weight declaration. | Extremely cold, sublimates (no liquid mess), lightweight | Can cause freeze burns, requires special handling, regulated |

| EPS Foam Coolers | High-value perishables, extended transit times (2+ days) | No specific shipping restrictions on the material itself | Excellent thermal insulation, durable, reusable | Bulky, higher cost, less environmentally friendly |

| Insulated Liners/Mailers | Short transit (overnight), less temperature-sensitive items | Works with other coolants; compliance depends on what's inside | Lightweight, space-saving, lower shipping costs | Less protective than hard coolers, not for extreme temperatures |

Ultimately, you're building a self-contained ecosystem for your product. It has to survive warehouse temperature swings, bumpy rides in a delivery truck, and sitting on a porch in the sun.

Pro Tip: Always run a test shipment before you go live. Pack a box exactly as a customer would receive it, toss in a temperature logger, and ship it to a friend or even back to yourself. It's the only real way to know if your packaging can handle the journey and keep your products safe.

Navigating State and Carrier Shipping Restrictions

If you think federal guidelines are the end of the road for compliance, I've got some bad news. Getting the hang of cold chain logistics and packaging is just the first step. The real fun begins when you dive into the tangled web of state and individual carrier rules.

This is where a one-size-fits-all shipping strategy completely breaks down. It's a quick way to end up with returned packages, unhappy customers, and a serious hit to your revenue.

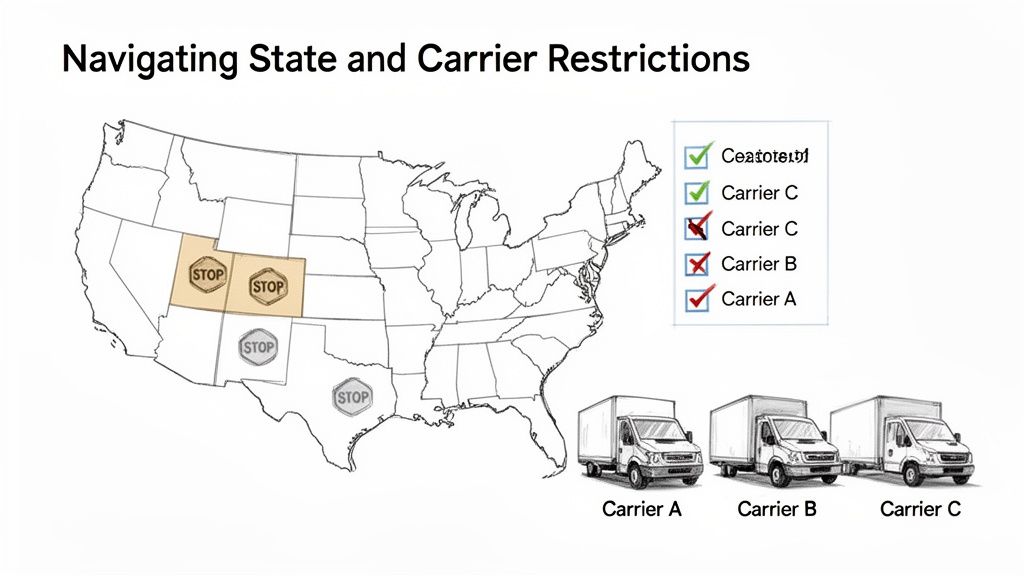

Think of federal rules as the main highway—everyone follows the same general speed limit. But state and carrier rules are the local roads. As soon as you take an exit, the speed limit changes, stop signs appear out of nowhere, and you're dealing with a whole new set of local ordinances. Ignoring them is just as costly.

The Patchwork of State-Level Rules

Many of the toughest perishable food shipping restrictions are actually enforced at the state level. The goal is usually to protect local agriculture from invasive pests and diseases. States with huge agricultural economies are famously strict, creating invisible borders your products might not be allowed to cross.

A few classic examples:

- California: The state has some of the most aggressive agricultural laws in the nation. Trying to ship certain fresh fruits, vegetables, or even live plants into California without the right certifications is a non-starter. A friendly gift box of homegrown citrus from a relative in Florida? It's likely getting confiscated.

- Florida: Much like California, Florida is fiercely protective of its citrus and produce industries. The state heavily regulates incoming plant and food materials to prevent contamination.

- Hawaii: With its incredibly unique and fragile ecosystem, Hawaii puts up a virtual wall. The state has extremely strict rules on nearly all agricultural products being brought in from the mainland.

These rules mean you can't just assume a product that's legal to ship from your state is legal for someone to receive in another. Every single destination address has to be vetted against a laundry list of regional restrictions.

How Major Carriers Add Another Layer of Complexity

On top of state laws, each shipping carrier—USPS, UPS, and FedEx—piles on its own unique set of rules for handling perishable goods. They are absolutely not interchangeable. A package you prepped perfectly for one carrier might be flatly rejected by another.

For instance, they all have rules for dry ice, but the specific labeling requirements and quantity limits can vary. One might demand a special form, while another is fine with the standard Class 9 HAZMAT label. These tiny details are what trip people up.

The assumption that all carriers treat perishable shipments the same is a costly mistake. Their policies on everything from live seafood to alcohol-infused foods can vary dramatically, and it's your responsibility as the shipper to know the difference before you print the label.

Comparing Carrier-Specific Perishable Policies

Let's break down some of the key differences you'll run into when picking a carrier for your perishable products.

United States Postal Service (USPS)

USPS is often a go-to for its cost-effectiveness, but it comes with a distinct rulebook. They’re fine with shipping live animals like bees and baby poultry, but forget about sending live lobsters. They also have very specific packaging rules designed to prevent leaks and odors that could ruin other mail.

United Parcel Service (UPS)

UPS offers some really solid services for perishables, but they demand strict adherence to their packaging standards, often recommending specific insulation thicknesses. They have detailed protocols for anything that might emit a strong odor, and you have to prove your packaging can contain it for the entire trip.

FedEx

FedEx is often the choice for high-value or extremely sensitive items, thanks to extensive temperature-controlled options like their "Cold Shipping Package." However, their rules for shipping things like alcohol-infused foods or other regulated items are highly specific and might even require pre-approval or a special contract.

These differences highlight why a dynamic shipping strategy is essential. For any business shipping regulated products, understanding the nuances between national and regional carrier options is fundamental to staying compliant.

And this web of rules is only getting more complex. The global perishable food shipping industry, valued at USD 21.7 billion in 2024, is facing immense pressure from new international mandates and tariffs. These shifts are expected to cause major volume losses on key routes and drive up logistics costs, making precise compliance more critical than ever. You can learn more about these evolving market dynamics from GlobeNewswire.

At the end of the day, trying to manually track this maze of state and carrier rules is an impossible task for a growing business. It screams for a system that can automatically apply these granular, destination-specific restrictions right at checkout.

How to Automate Compliance and Prevent Shipping Errors

<iframe width="100%" style="aspect-ratio: 16 / 9;" src="https://www.youtube.com/embed/BmJuPzCN3d8" frameborder="0" allow="autoplay; encrypted-media" allowfullscreen></iframe>Once you start mapping out the web of federal, state, and carrier rules, one thing becomes painfully clear. Manually checking every single order for compliance isn't just a bottleneck—it's a recipe for disaster. The sheer number of variables makes human error almost inevitable.

Imagine your team trying to remember if a specific type of fresh citrus is banned in three California counties, while also confirming that a customer in rural Texas can even receive a package with dry ice via their chosen carrier. This manual grind is slow, frustrating, and incredibly risky. A single mistake can lead to a confiscated shipment, a hefty fine, or a permanently lost customer.

This is where a modern, automated solution isn't just helpful; it's essential. An automated rules engine acts as a digital gatekeeper, providing a reliable and instantaneous safety net for your eCommerce store. It simply eliminates the guesswork and the potential for costly errors.

The Power of an Automated Rules Engine

Think of an automated system as your smartest, fastest, and most knowledgeable compliance officer, working 24/7. Instead of relying on checklists, binders, and memory, you can build a library of digital rules that automatically vet every order at checkout.

This technology works by instantly cross-referencing three key pieces of data:

- The products in the customer's cart.

- The customer's complete shipping address (state, county, city, and ZIP code).

- The shipping methods available for that destination.

Based on the rules you create, the system can then allow, modify, or block the order before the customer even finishes their purchase. This proactive approach is the difference between preventing a problem and cleaning up a mess.

Putting Automation into Practice

The real power of this technology lies in its granularity. You can create highly specific rules that address the exact perishable food shipping restrictions that affect your products.

For example, you could set up rules like:

- "If a customer from California adds fresh oranges to their cart, block the order and show a message explaining the state's agricultural restrictions."

- "If an order contains frozen seafood, automatically hide all shipping options except for Priority Overnight."

- "For any shipment containing dry ice, only show shipping methods from carriers that accept HAZMAT packages for that specific route."

Here’s a look at how you can build and manage these rules in a modern system.

The screenshot shows a clear, organized dashboard where rules are defined with specific conditions and outcomes, making complex compliance logic simple to manage. This level of control allows you to transform your shipping strategy from reactive to proactive, ensuring every package that leaves your facility is fully compliant from the start.

An automated compliance system turns a massive, complex problem into a simple, manageable process. It saves countless hours of manual work, prevents expensive shipping errors, and protects your business from the financial and reputational damage of non-compliance.

For businesses running on platforms like WooCommerce, this level of control is not a far-off dream. You can learn more about how to get started with automated shipping compliance for WooCommerce stores to see how these tools integrate directly into your existing workflow. By implementing a rules-based system, you can scale your business with confidence, knowing that a critical part of your operation is handled automatically and accurately, every single time.

Building a Compliant Perishable Shipping Strategy

Successfully shipping perishable food isn't just a race against the clock—it's a carefully executed strategy built on deep product knowledge and operational precision. The entire process hinges on three core pillars: understanding your product’s unique needs, mastering temperature and packaging protocols, and navigating a complex maze of shipping regulations. If any one of these pillars crumbles, the whole shipment is at risk.

The costs of getting it wrong are steep and immediate. We're talking spoiled products, returned shipments, unhappy customers, and a lasting stain on your brand’s reputation. A single mishandled order can vaporize the trust you've worked so hard to build. That’s why shifting from a reactive, "fix-it-when-it-breaks" mindset to a proactive compliance strategy is absolutely essential for growth.

From Reactive to Proactive Compliance

A proactive strategy turns shipping from a constant source of anxiety into a powerful competitive advantage. It's all about anticipating challenges and putting systems in place to prevent errors before they can ever happen. This means creating a comprehensive game plan that covers every single step of the journey, from your warehouse to the customer's doorstep.

Key components of a solid proactive strategy include:

- Product-Specific Protocols: Nailing down the exact packaging, coolant type, and shipping speed required for each and every item you sell. A pint of ice cream and a block of cheese have very different needs.

- Carrier Rule Mastery: Knowing the specific requirements of each carrier you work with, especially when it comes to tricky items like dry ice and the HAZMAT labels that go with it.

- State-by-State Awareness: Keeping a clear, updated map of which products are restricted in which states to avoid automatic rejections and returned packages.

By mastering the rules, you're not just shipping a product; you're delivering reliability and a commitment to quality. This is the kind of consistency that turns one-time buyers into loyal, repeat customers who trust you to get it right every single time.

Automation is the key to making this proactive approach manageable, especially as you scale. Instead of having a human manually check every single order against a spreadsheet, a rules-based system can ensure every shipment is compliant from the moment of purchase. This frees you up to grow your business with confidence, knowing each order is being shipped safely and legally. Of course, keeping detailed records is also part of a strong strategy, and you can learn more about the importance of shipping restriction record-keeping in our detailed guide.

Got questions about the nitty-gritty details of shipping perishable food? You're not alone. Here are a few of the most common head-scratchers we see from eCommerce store owners, with straight-up answers.

Can I Ship Perishable Food Internationally?

Yes, but buckle up—it's a whole different level of complexity. Think of it as the expert mode of food shipping.

On top of all the domestic rules, you're now dealing with the destination country's customs agents, their specific food safety standards, and a mountain of import paperwork. Every country has its own "do not ship" list, and a single mistake on a customs form can get your package flagged.

Transit times are also way longer, which means your cold chain packaging has to be bulletproof. I'm talking serious insulation and long-lasting coolants. Partnering with an international carrier who specializes in this is a must-have, not a nice-to-have. Otherwise, you risk your shipment being seized or, worse, destroyed at the border.

What Is the 2-Hour Rule for Perishable Food Safety?

This is a big one. The "2-Hour Rule" is a fundamental food safety guideline straight from the USDA. It’s pretty simple: any perishable food that sits in the "Temperature Danger Zone" (between 40°F and 140°F) for over two hours needs to be thrown out.

For shippers, this rule is your guiding star. It means your packaging can't just be "good enough"—it has to keep the inside of that box below 40°F for the entire trip, plus a safety cushion for inevitable delays. This is exactly why slapping a "Perishable" sticker on a box and sending it via ground shipping is a recipe for disaster.

This isn't just a friendly suggestion; it's a core principle protecting customer health and your reputation. As the shipper, the responsibility to maintain that cold chain rests squarely on your shoulders, even if the carrier hits a snag along the way.

How Do I Properly Label a Package Containing Dry Ice?

If you're using dry ice, you're officially shipping hazardous materials (at least for air travel), and that comes with some very specific, non-negotiable labeling rules. Get this wrong, and you're looking at carrier fines and rejected shipments.

You have to follow these steps to the letter:

- Get the Right Sticker: You'll need a Class 9 Miscellaneous Dangerous Goods label. It's the black-and-white diamond-shaped one.

- Mark the Box: The outside of the package needs to be clearly marked with the words "Carbon Dioxide, Solid" or "Dry Ice."

- State the Net Weight: You must declare exactly how much dry ice is in the box, measured in kilograms.

- Include Shipper/Recipient Info: As with any package, the sender's and receiver's information must be easy to read.

One last critical point: your package must be able to vent. Dry ice turns from a solid into carbon dioxide gas, and if that gas has nowhere to go, the pressure can make your package rupture or even explode. Always double-check your carrier's latest guidelines before you ship, because these rules can and do change.

Trying to keep all these rules straight for every order is a huge headache for a growing business. Ship Restrict takes the guesswork out of it by letting you build these compliance checks right into your WooCommerce store, stopping costly shipping mistakes before they ever happen. See how it works at https://shiprestrict.com.

Cody Yurk

Founder and Lead Developer of ShipRestrict, helping e-commerce businesses navigate complex shipping regulations for regulated products. Ecommerce store owner turned developer.