How to Handle Split Orders When Some Products Can't Ship Together | Tips & Strategies

Learn how to handle split orders when some products can't ship together. Discover effective strategies and automation tips for seamless customer service.

Cody Y.

Updated on Oct 2, 2025

Dealing with orders that contain items that just can't ship together demands a smart, automated game plan. The key is to use a system that spots these shipping conflicts right in the cart, tells the customer exactly what's happening at checkout (including separate costs), and makes it easy for you to manage multiple shipments for one order on the back end.

The Growing Challenge of Complex Shipments

Let's be honest—managing orders with items that can't be packed in the same box is a massive operational headache. A customer might order a fragile glass vase and a heavy kettlebell, or a frozen meal and a shelf-stable pantry item. These scenarios create logistical puzzles that can quickly lead to shipping errors, frustrated customers, and ballooning costs if you don't have a solid process in place.

This isn't just a rare inconvenience anymore; it's a growing reality for modern online stores. The reasons are all over the map and show just how complex today's retail world has become.

Let's break down some of the most common logistical hurdles that force orders to be split. Seeing these real-world examples can help you pinpoint exactly what's causing fulfillment challenges in your own store.

Common Reasons Products Cannot Ship Together

A quick look at the real-world logistical challenges that force orders to be split, helping you pinpoint the exact issues affecting your store.

| Shipping Challenge | Example Scenario | Impact on Customer Experience |

|---|---|---|

| Multiple Warehouse Locations | A customer orders a t-shirt from your main warehouse and a specialty hat that only ships from a secondary location in another state. | The customer gets two packages at different times, which can be confusing without clear communication and separate tracking numbers. |

| Special Handling Requirements | An order includes a refrigerated food item that requires cold packs and overnight shipping, plus a non-perishable canned good that can go via standard ground. | Without splitting, you'd be forced to pay exorbitant overnight rates for the canned good. Splitting is essential for cost control. |

| Pre-Orders & In-Stock Items | A customer buys an in-stock coffee mug and also pre-orders a new video game that won't be released for another two months. | The customer expects the mug now, not in two months. Holding the entire order would create a terrible experience and likely a cancellation. |

| Drop-Shipping & Print-on-Demand | Your store sells branded merchandise. A customer orders a sweatshirt you stock yourself and a phone case that is printed and shipped directly from a third-party supplier. | You have no control over the phone case fulfillment. The order must be split because it originates from two different fulfillment points. |

As you can see, these aren't edge cases. They're everyday situations for stores with diverse product catalogs and supply chains.

Why This Problem Is Getting Worse

The explosive growth of e-commerce has made split shipments a much more frequent issue, and it's hitting logistics hard. As online sales have climbed, the rate of split shipments has jumped from about 1.2% to 1.8%, causing delivery expenses to skyrocket. Often, this is because of outdated inventory data that isn't syncing fast enough across different systems.

Turning a logistical challenge into a competitive advantage is all about transparency. When you clearly explain why an order is split and provide separate tracking, you're not creating a problem—you're demonstrating professional, efficient fulfillment.

To get a handle on the complexities that split orders bring, businesses have to focus on effective strategies for optimizing supply chain management. This isn't just about fixing a logistical snag. It’s a chance to build real trust with your customers by being upfront and organized, turning a potentially confusing situation into a smooth and professional experience.

Configuring Your Store to Recognize Shipping Conflicts

Trying to manually catch every order with a shipping conflict is a losing battle and a recipe for mistakes. Instead, you can teach your WooCommerce store to recognize these conflicts automatically. The secret is creating logical Shipping Groups, a powerful way to categorize products based on their specific fulfillment needs.

Think of these groups as simple buckets for items with similar shipping rules. You might create one group for "Perishables" that need cold packs, another for "Oversized" items that ship via freight, and a third for all your "Standard" products. Once a product is in a group, the system knows it can only ship with other items from that same group.

Getting this configuration right upfront is the key to managing split orders without headaches. You're building the intelligence directly into your store, which stops fulfillment problems and costly shipping errors before they can happen.

Setting Up Your First Shipping Groups

Your first move is to look at your product catalog and identify the distinct shipping requirements. Do you sell items that ship from different warehouses? Do some products need special handling or packaging? These natural divisions are the perfect starting point for creating your groups.

Here are a few common, real-world examples to get you thinking:

- Perishables Group for items needing refrigerated shipping.

- Heavy Items Group for products that exceed standard carrier weight limits.

- Print-on-Demand Group for merchandise fulfilled by a third-party service.

- Hazmat Group for products with specific shipping regulations.

By creating these logical separations, you’re putting clear rules in place for your fulfillment team. This makes split orders, where you ship items from a single purchase separately, a smooth and efficient part of your operation. For example, if a customer buys both clothing and electronics, those items often ship from different warehouses. Shipping them from their respective locations gets them to the customer faster and with better tracking.

The goal isn't to create dozens of complex groups. Start with two or three of your most obvious shipping conflicts. You can always add more later as your product line expands or your fulfillment strategy evolves.

Assigning Products to Their Groups

Once you have your groups established, the next job is to assign each relevant product to its correct category. This is where you tell WooCommerce which items can’t share a shipping box. For instance, a frozen pizza goes into the "Perishables" group, while a pizza cutter goes into the "Standard" group.

Now, if a customer adds both to their cart, your store will instantly recognize the conflict. This is far more reliable than expecting a busy warehouse team member to remember hundreds of unique product rules. For a detailed walkthrough, check out our guide on how to restrict shipping by product in WooCommerce, which breaks down the process step-by-step.

The process itself is straightforward, but the impact is massive. By methodically categorizing your products, you're building a dependable, automated system that knows exactly how to handle split orders, laying the foundation for a seamless checkout experience.

Automating the Cart Split for a Seamless Checkout

Okay, so you’ve set up your product shipping groups. That’s the heavy lifting done. Now, let's put that hard work on autopilot. The real magic happens when you automate the cart split, creating a checkout process that feels completely intuitive for your customers.

The whole point is to eliminate friction. When someone adds items from different fulfillment groups—say, a print-on-demand t-shirt and a hat you stock in your own warehouse—the system should instantly catch the conflict. Instead of showing a single confusing shipment, it needs to dynamically create two separate "packages" right there in the cart.

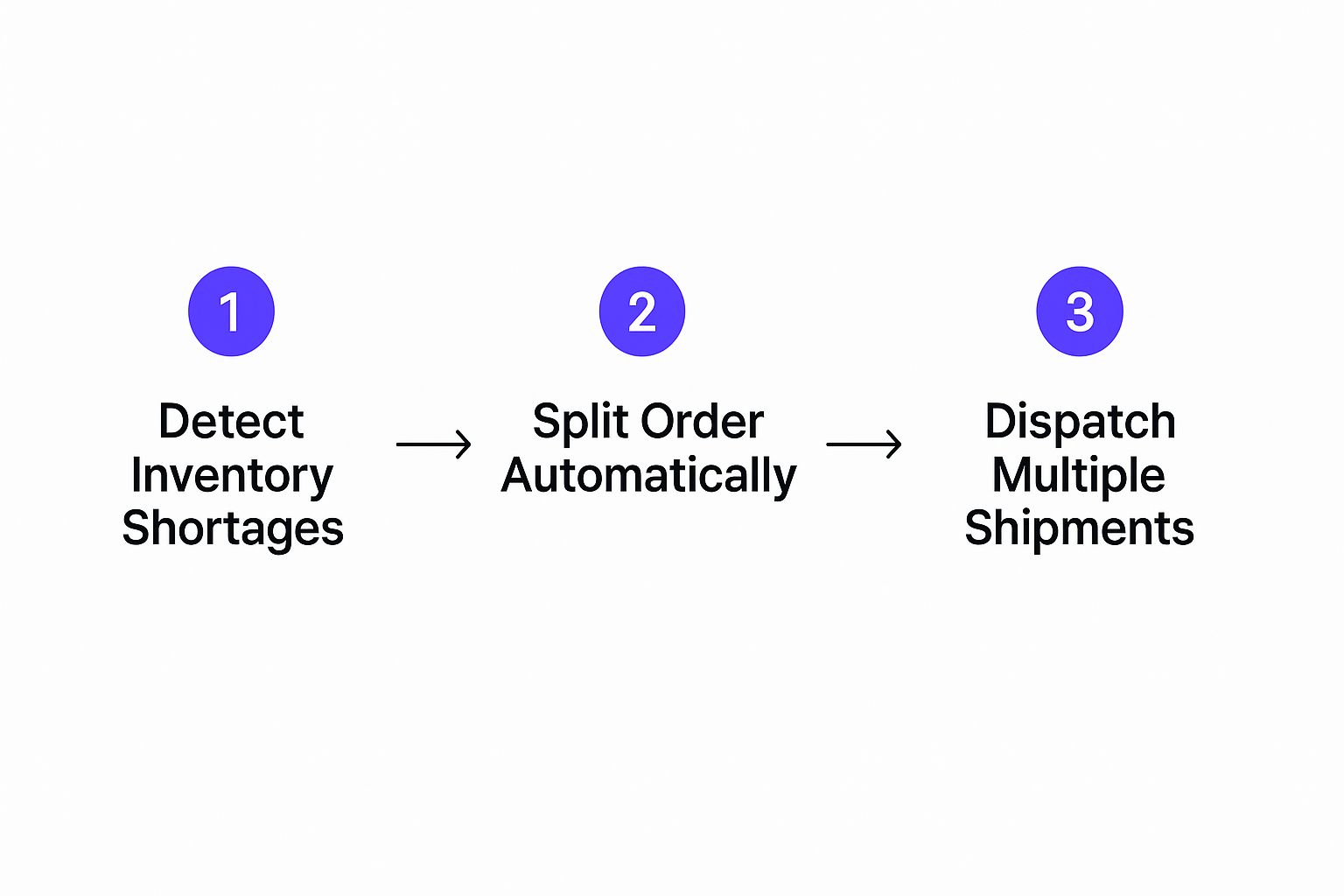

This flowchart gives you a bird's-eye view of how a smart system detects different fulfillment needs, splits the order, and sends the shipments on their separate ways.

This kind of automation is what saves your team from the headache of manual adjustments and stops human error in its tracks.

Crafting a Clear Checkout Experience

Transparency here is everything. The absolute worst thing you can do is surprise a customer with unexpected shipping costs or multiple boxes they weren't expecting. A properly configured system presents the split checkout clearly and honestly.

It should look something like this:

- Shipment 1 From Our Main Warehouse

- Item A: Classic Baseball Cap

- Shipping Method: Standard Ground - $5.00

- Shipment 2 From Our Printing Partner

- Item B: Custom Graphic T-Shirt

- Shipping Method: Standard - $4.50

This approach does two crucial things. First, it tells the customer why their order is split, which builds a surprising amount of trust. Second, it calculates and shows the right shipping cost for each package, so there are no nasty surprises. This clarity alone can dramatically cut down on cart abandonment and those "Where's the rest of my order?" support tickets.

When you automate cart splitting, you're not just solving a logistics problem; you're designing a better customer journey. The system handles the complexity so the shopper only sees a clear, logical, and honest checkout process.

Why Automation Prevents Costly Errors

Relying on a human to catch every mixed cart is a recipe for disaster. Expecting your team to manually calculate blended shipping rates or create separate orders just doesn't scale. It's a system that's bound to break, leading to:

- Inaccurate Shipping Charges: Undercharging for shipping on a two-box order is a direct hit to your profit margins.

- Fulfillment Delays: Every minute spent manually fixing an order is a minute that order isn't being picked, packed, and shipped.

- Poor Customer Experience: Nothing sours a sale faster than having to contact a customer after they've paid to ask for more money for shipping.

By automating the split, you guarantee every order is priced and processed correctly the second it’s placed. This is a huge part of automated shipping compliance for Woo-Commerce stores, where you let rules-based logic do the heavy lifting.

While getting the cart split right is critical, don't stop there. Think about optimizing your WooCommerce checkout experience as a whole. The smoother you make the entire journey, the more likely customers are to follow through with their purchase, even if it involves a slightly more complex shipment.

Communicating Split Shipments Clearly to Customers

Automating the cart split is a solid first step, but it's only half the battle. The other half is communicating that split so effectively that your customers feel informed, not blindsided.

Nothing kills a conversion faster than a surprise at checkout, and a poorly explained split order is a major source of friction. Your job is to manage expectations from the get-go, turning what could be a logistical headache into a showcase of your store's professionalism.

The conversation starts right on the checkout page. This is your first and best chance to frame the split as a good thing. Forget generic alerts—use clear, reassuring language that explains exactly what's happening and, more importantly, why.

Crafting the Perfect Checkout Message

Drop the technical jargon. Your customers don't need to know about "fulfillment groups" or "shipping profiles." They just want simple, direct information that makes sense in the context of their purchase.

For instance, say a customer orders a refrigerated item and a pantry staple. A great on-screen message would be:

To ensure your refrigerated items stay fresh, they will ship separately via expedited service. You'll receive a separate tracking number for each package so you can follow them right to your door!

This message is effective because it:

- Explains the "Why": It immediately addresses the reason for the split—keeping items fresh.

- Sets Clear Expectations: It tells them to expect two packages and two tracking numbers. No surprises.

- Frames it as a Benefit: The underlying message is that you're taking extra care to get their order right.

When you nail this first touchpoint, you teach customers how your store handles these kinds of orders, building trust from their very first purchase.

Essential Post-Purchase Communication

Once the order is placed, your communication can't stop. A single, confusing order confirmation email for a two-shipment order is a recipe for support tickets. The best practice here is to send separate confirmation and shipping notification emails for each part of the order.

Your post-purchase email flow should look something like this:

- An Immediate Order Confirmation: This email should recap the entire order but clearly break it down into the two separate shipment groups.

- Shipment Notification Email #1: Sent when the first package leaves your warehouse. This email must contain only the items in that specific box and its unique tracking number.

- Shipment Notification Email #2: This follows the exact same format as the first but is for the second package, with its own distinct item list and tracking link.

This level of detail might seem like overkill, but it's crucial for transparency. When a customer receives the first box, they can instantly check their email and see exactly what was supposed to be in it. This completely eliminates that "Where's the rest of my stuff?" panic.

It’s a straightforward system that reinforces trust and dramatically cuts down on customer service inquiries.

Managing Split Orders from the Admin Dashboard

<iframe width="100%" style="aspect-ratio: 16 / 9;" src="https://www.youtube.com/embed/cVekm5xs3u0" frameborder="0" allow="autoplay; encrypted-media" allowfullscreen></iframe>Once you’ve automated the customer-facing side of split shipping, the real work begins in your WooCommerce admin dashboard. A well-configured system doesn’t create more chaos—it brings a new level of clarity and control to your entire fulfillment process.

When a customer’s cart contains items that can’t ship together, Ship Restrict automatically generates two (or more) separate but linked orders on the backend. This is a game-changer. Instead of one confusing order with conflicting shipping needs, you get clean, actionable tasks for each shipment.

This means a single customer transaction appears as distinct orders, each with its own unique order ID. You can immediately see which items belong to which shipment, preventing mix-ups and ensuring nothing falls through the cracks.

A Typical Fulfillment Workflow

Let's walk through a common scenario. Imagine a customer buys a stocked accessory that you fulfill from your primary warehouse and a custom part that drop-ships directly from a supplier.

In your dashboard, you'll see two linked orders. Your warehouse team can immediately process the first order for the in-stock accessory. They pick, pack, and ship it, then add the tracking number to that specific order. That part of the transaction is done.

Meanwhile, the second order for the custom part can be forwarded to your supplier or handled independently. When they provide a tracking number, you simply add it to its corresponding order. The two fulfillment paths never cross, yet they remain linked to the original customer purchase for easy reference.

This isn't just about better organization. It's about empowering independent fulfillment. Your warehouse team can work on their orders without waiting for the drop-shipper, and vice-versa. This simple change boosts efficiency and gets products to your customer faster.

The Impact on Inventory and Efficiency

Managing split orders this way directly improves your entire operation. By treating each shipment as a separate order, you gain precise control over your inventory and fulfillment queues.

- Improved Inventory Accuracy: Stock levels for each location are updated independently as items are shipped, which drastically reduces the risk of overselling.

- Streamlined Fulfillment: Each team or location sees only the orders they are responsible for, eliminating confusion and wasted time.

- Simplified Management: If you need to manage rules for many products at once, you can use tools for WooCommerce bulk shipping management to apply changes across your entire catalog in minutes.

This structured approach is proven to deliver tangible results. B2B e-commerce businesses that integrate split shipment functionality with their inventory systems have reported a 15-25% increase in inventory turnover rates. This efficiency leads to faster stocking cycles and a greater ability to handle complex orders without a hitch.

Ultimately, a well-managed backend turns the challenge of split shipping into a smooth, scalable process that benefits both your team and your customers.

Common Questions About Handling Split Orders

Even with a perfectly configured system, you're bound to have questions about how to handle split orders. This strategy touches everything from customer perception to shipping costs, so it’s natural to want clarity on the details. Let's dig into the most common concerns that pop up when stores start splitting shipments.

Getting these answers straight will help you troubleshoot issues and feel confident that you’re making the right moves for both your business and your customers.

Will Splitting Orders Hurt My Conversions?

This is the number one concern I hear, and the answer is a firm no—as long as you’re transparent about it. When a checkout page clearly shows two separate shipments and explains why (think: "Items from our refrigerated warehouse ship separately"), it actually builds trust.

Most customers get it. They understand that getting some items quickly is better than waiting for everything to be bundled together. Proactive communication is huge here. Following up with emails that include separate tracking numbers for each package keeps customers in the loop and turns a potential point of confusion into a positive experience that highlights your professional fulfillment process.

The key takeaway is that clarity trumps everything. A well-informed customer is a happy customer, and a checkout process without surprises is one that converts.

How Does Splitting Orders Affect Shipping Costs?

The great thing is that you stay in complete control. Your system will calculate the rates for each package based on the shipping rules you’ve already set up in WooCommerce, whether that’s live UPS rates or simple flat fees. From there, you have a few strategic options:

- Pass the exact cost along: The customer simply pays the combined, accurate total for both shipments.

- Subsidize the second shipment: You can absorb some or all of the cost for the second box as a courtesy.

- Offer conditional free shipping: If the total cart value meets your free shipping threshold, you can apply it to both packages.

The primary advantage here is accuracy. You no longer have to guess at a blended shipping rate or risk undercharging for an order that genuinely needs two separate boxes and two shipping labels.

Can I Just Manually Split an Order?

Technically, you can, but it's a messy and highly error-prone workaround. A manual split often means canceling the original order and asking the customer to place two new ones. That's a terrible experience that will almost certainly lead to an abandoned purchase.

The alternative is handling the second shipment "off the books," which creates a nightmare for your inventory counts and accounting. Automating the split right at the moment of checkout is far more professional, efficient, and scalable for both your team and your customers.

Ready to stop wrestling with complex shipments and start automating your fulfillment? With Ship Restrict, you can set up intelligent rules that automatically handle orders when some products can't ship together, creating a seamless experience for you and your customers. Take control of your shipping logic by visiting https://shiprestrict.com today.

Cody Yurk

Founder and Lead Developer of ShipRestrict, helping e-commerce businesses navigate complex shipping regulations for regulated products. Ecommerce store owner turned developer.